SPECIALTY METALS

OVERVIEW

ZALMAG® is a steel based product with a unique coating consisting of Zinc, Aluminum and Magnesium.

ZALMAG® is a highly corrosion – resistant, hot dip coated steel that has a coating layer of Zinc, Aluminum, and Magnesium. Additionally, ZALMAG® has superior scratch resistance with unique self-healing characteristics that make it the perfect material for perforating and a great solution for all environments.

PATINA PROCESS

The beauty and magic of ZALMAG® is that every application is different. Depending on the temperature, humidity, and alkalinity of your location, the patina process can start at different rates (days to years) adding visual interest and character at every step of the journey. ZALMAG® makes any architectural application a living transformation project.

ZALMAG® surfaces (Natural, Pre-Patina II, and Black) will age in a random order to grey tones. Grey-to-white marks can appear on ZALMAG®’s surfaces; these marks do not adversely affect the material’s lifespan but add to it’s forever-changing characteristic. ZALMAG® reacts to the environment, handling, installation, and equipment pressure. Due to the nature of ZALMAG®, it will self-heal cuts and perforations and it will naturally patina based on handling and the surrounding environment.

The immediate cleaning of ZALMAG® is more effective at preserving the aesthetics of the ZALMAG® surface than waiting to clean. However, ZALMAG® is a naturally aging metal and will use surface deposits and environmental effects to patina it’s surface (including fingerprints). Please note, fingerprints are common on ZALMAG® surfaces, as ZALMAG® ages the fingerprints will age and blend with the surface patina.” Fingerprints which occur on the metal surface due to sweat on the skin may not be completely covered by natural weathering over time, dependent on intensity, and may be visually conspicuous for a long period of time. To avoid color blocking or stair stepping, it is important to complete sections of the installation simultaneously. If there are long delays, it should be expected that color and patina differences will occur. This means the material is doing what it is supposed to which is react to the environment it’s exposed to and begins to patina immediately.

AVAILABLE FINISH 01:

Natural ZALMAG®

Natural ZALMAG® begins as spangled metallic silver and ages into an attractive matte gray with hints of blue. During the patina process, the ZALMAG® acts as a sponge absorbing anything that comes in contact with the material. Water droplets, dust, and other contaminates can be evident on the surface as the metal begins to age in it’s environment.

The Gantry Building Apartments Long Island City, NY

Architect: GKV Architects

Product: Large Cupped Tile

Finish: Natural

Dordt College Sioux Center, IA

Architect: Hastings & Chivetta

Product: Large FlatTile

Finish: Natural

Blues Egg Shorewood, WI

Architect: The Consortium ae

Product: Diamond Tile

Finish: Natural

AVAILABLE FINISH 02:

Pre-Patina II ZALMAG®

Pre-Patina II ZALMAG® is a gray-coated ZALMAG® that provides a patinaed look immediately upon installation. This product will continue to age and change slightly in gray hue over time, even with gray coating

Trapp Farm Eagen, MN

Architect: Oertel Architects

Product: Large Flat Tile

Finish: Pre-Patina II

Dyna Energetics Blum, TX

Architect: Arch11

Product: Custom

Finish: Pre-Patina II

AVAILABLE FINISH 03:

Black ZALMAG®

Black ZALMAG® is best described as having a “charred wood” look from afar with a leather texture up-close. It will also present typical coated ZALMAG® aging patterns across its face over time.

111 E. Grand Des Moines, IA

Architect: Neumann Monson Architects

Product: Tongue & Groove reveal panel

Finish: Black

Cobalt Credit Union Gretna, NE

Architect: HDR Inc.

Product: Lay-Flat Panel (double offset)

Finish: Black

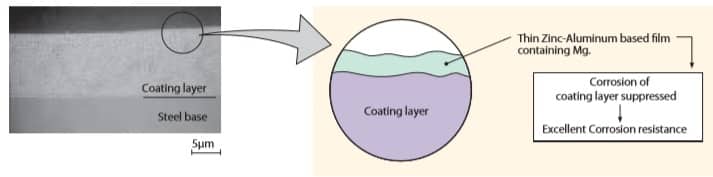

THE ULTIMATE IN CORROSION RESISTANCE

The Zalmag® coating is a blend of zinc, aluminum and magnesium. The small quantities of magnesium (3%) and aluminum (6%) combine to form a protective barrier on the surface of the coating over time. The fine, strongly attached barrier creates a two-layer structure on the surface of the steel, suppressing corrosion resistance of the product. With a corrosion resistance at least 3 times that of zinc galvanized steel for the same coating mass, Zalmag® products can be used in environments subject to extremely corrosive conditions.

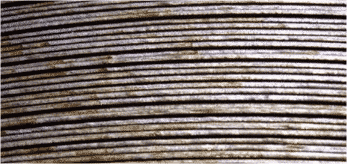

SELF-HEALING CHARACTERISTICS

Excellent corrosion resistance is achieved on cut end parts by the sacrificial anti-corrosive effect of the coating. Initially, cut edges may display signs of red rust, but this will change color over time as the protective mechanism converts the red rust to a grey-black, highly corrosion resistant coating. The color tone and the speed at which the tone changes vary depending on the exposure environment (region, installation location, orientation, etc.) A slit coil shows the results of self-healing within just two weeks.

ZALMAG® PROJECTS