The Evolution of the Flat Lock Panel, the Lay-Flat Panel System

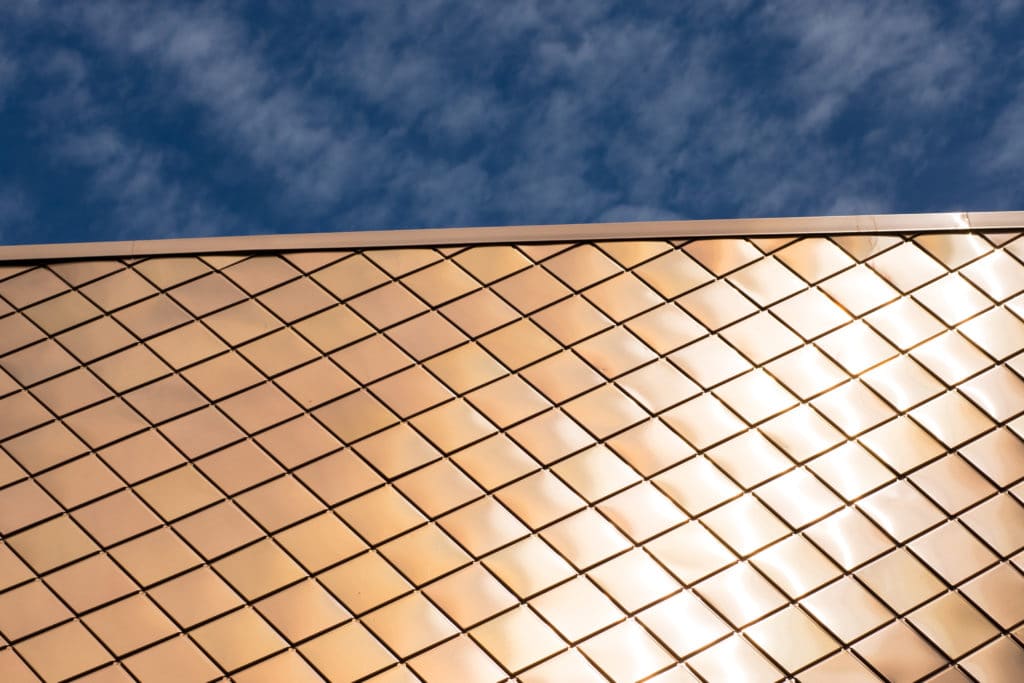

When talking metals panels systems, the flat lock panel is an industry standard for commercial and residential projects alike. Take a walk through any major city and you will notice an abundance of Flat Lock panels on apartment complexes, loft buildings and businesses. A great cladding solution that can be cost effective but also appear high end with a wide range of different types of metals to choose from.

Architects have the option of using a variety of metals like copper, zinc, stainless steel, ZALMAG and more. Along with the material choices there are many different options for different panel sizes and gauge thicknesses. Flat Lock panels can look great with the proper installation and material specification but that is not always the case.

The biggest fear when an architect is specifying a metal panel system is oil canning. What exactly is oil canning? Think of the old metal oil cans used to lubricate mechanical metal parts. These metal cans often showed an abundance of small dents and waves in the metal due to the thin gauge material. The same thing can apply when using metal cladding or roofing on any building. The last thing an architect wants to see when choosing metal is a wavy looking panel. So how do you avoid your next metal panel facade from looking oil canned?

*Hover and click to enlarge images

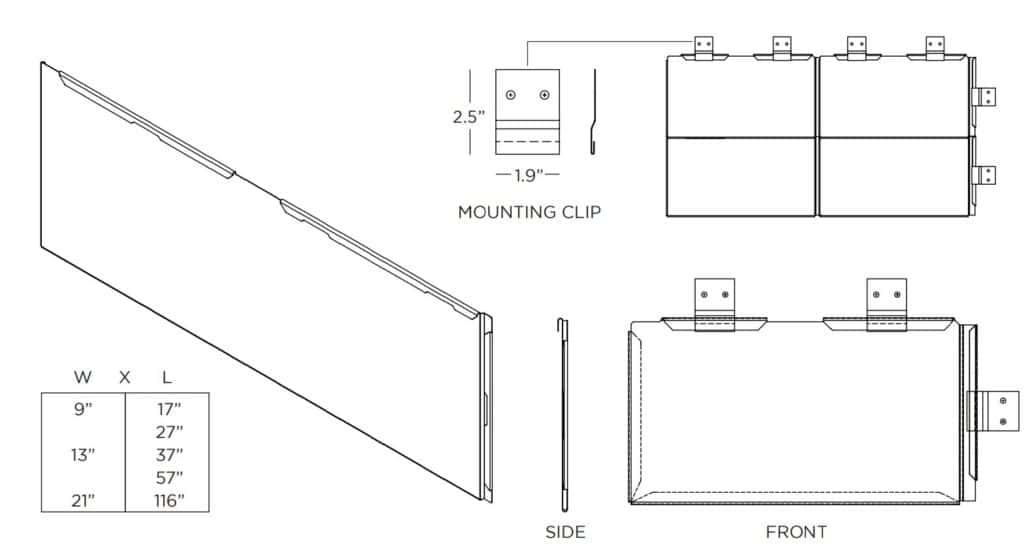

The Flat Lock panel is great because it is a simple break-formed panel that can be made at a relatively low cost. Installation requires metal clips to fasten the panel directly to the substrate which allows the panels to expand and contract. Looking at a flat lock panel, you will notice how the panels overlaps each panel on all four sides to create a fish scale or shingle-like appearance. The idea is great and creates a unique dimensional metal facade.

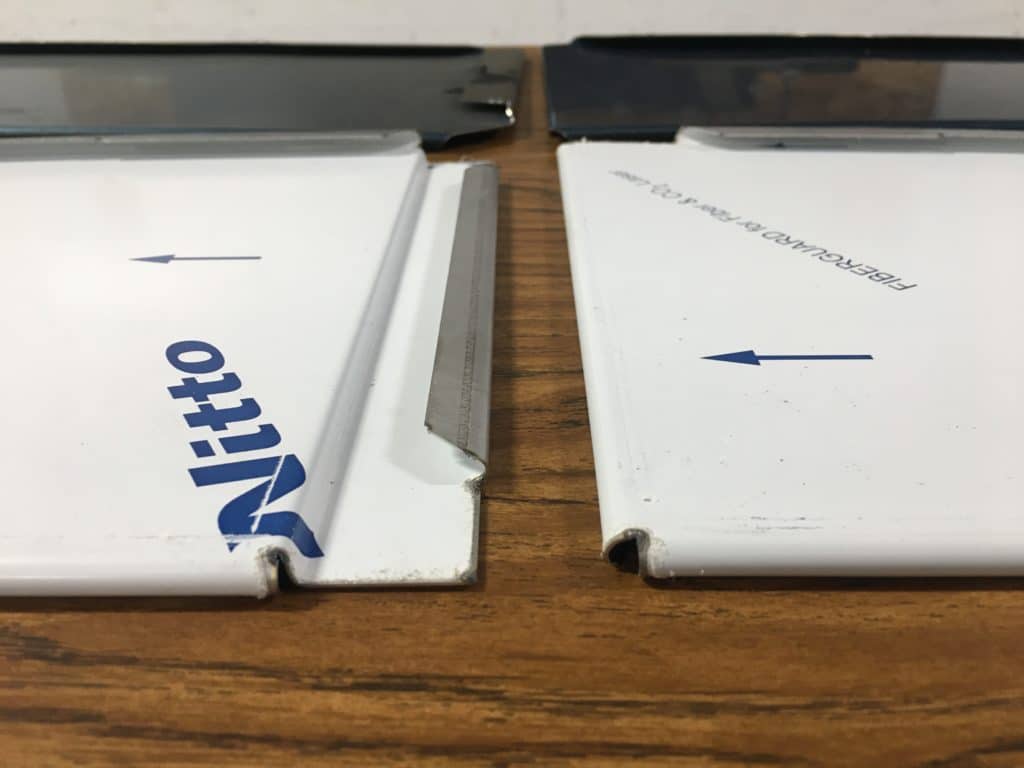

The downside of these overlapping panels is the tension created during installation. When overlapping several panels at different depths, you create a stress point on the panel and ultimately flexing the metal to make each part fully interlock. If the correct gauge metal or material type is not specified, it is very easy for these panels to appear oil canned. There is nothing worse than completing a high-end metal facade only to notice waves across the shiny new metal.

The solution is simple, a Lay-Flat panel gives the same overlapping appearance without the added stress on the panels. The Lay-Flat panel has the same hems and layout as your standard flat lock panel but with an added relief bend on the right-side hem. Adding a relief hem allows panels to lay flat and no longer flex when trying to install on top of two existing panels. The concept is simple, but the result is a streamlined metal panel with absolutely zero oil canning. Your installers will thank you when they realize how much easier it is to install and make a metal facade look perfect when choosing Lay-Flat over Flat Lock.

To learn more about the differences between the Flat Lock and Lay Flat Panel Systems, checkout the panel section of our website.

Millennium Forms panel options

Related Project Spotlights

The Evolution of the Flat Lock Panel, the Lay-Flat Panel System

The Evolution of the Flat Lock Panel, the Lay-Flat Panel System When talking metals panels systems, the flat [...]

Linda Sokol Francis Brookfield Library

Linda Sokol Francis Brookfield Library LIC Stainless Steel adds a durable and colorful façade to the LSF Brookfield Library [...]

John Cotton Dana Library

John Cotton Library at Rutgers University John Cotton Dana Library - Newark, NJ The John Cotton Dana Library is the physical [...]

Williams Park Field House

Williams Park Field House Williams Park Fieldhouse - Chicago, IL The Williams Park Fieldhouse in the south side of Chicago is [...]

Children’s STAR & Developmental Center

Children’s STAR & Developmental Center Children's STAR & Development - West Des Moines, IA The Blank Children’s STAR & Developmental Center [...]

Eric Baker Nord Performing Arts Annex

ERIC BAKER NORD PERFORMING ARTS ANNEX Eric Baker Nord Performing Arts Annex at Oberlin College - Oberlin, OH The Eric Baker [...]

Christ Church Grammar School

CHRIST CHURCH GRAMMER SCHOOL Christ Church Grammar School - Perth, Australia The Christ Church Grammar School is located in Perth, Western [...]

BOISE STATE UNIVERSITY – CENTER FOR THE VISUAL ARTS

BOISE STATE UNIVERSITY - CENTER FOR THE VISUAL ARTS Center for Visual Arts at Boise State University - Boise, ID The Center for [...]

111 E Grand

111 E GRAND Black ZALMAG® Adds Texture and Richness to this Innovative Office Space 111 E Grand - [...]